In the realm of industrial materials, marbled ebonites stand out as a fascinating intersection of artistry and scientific precision. These unique compounds, derived from rubber, have garnered attention for their aesthetic appeal and exceptional durability. Exploring the artistry behind their creation and the scientific principles that make them essential in the rubber industry.

The Art of Marbling

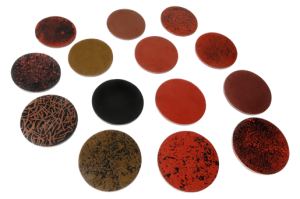

At the core of marbled ebonites lies a centuries old technique known as marbling. Artisans skillfully blend pigments on the surface of water, crafting intricate patterns transferred onto ebonite substrates. This delicate process demands a keen eye for design and a steady hand to achieve desired aesthetic effects. Whether featuring subtle swirls or bold bursts of color, each marbled ebonite piece stands as a unique work of art, showcasing the skill and creativity of its maker.

The Science Behind the Beauty

Beneath its mesmerizing surface, marbled ebonite conceals a wealth of scientific ingenuity. The composition of rubber compounds, combined with precise control of temperature and pressure during manufacturing, ensures the material’s durability and resilience. Advanced techniques in polymer chemistry have further refined ebonites, enhancing their properties such as resistance to abrasion, chemicals, and UV radiation. This fusion of art and science results in marbled ebonites that not only look stunning but also perform exceptionally well in various applications.

Applications and Versatility

The applications of marbled ebonites span across a diverse range of industries, from luxury pen manufacturing to aerospace engineering. In the realm of writing instruments, marbled ebonite fountain pens are prized for their elegance and comfort. Industrial sectors rely on ebonite components for critical applications, such as seals and insulators in machinery and electrical equipment. Moreover, the material’s resistance to corrosion and extreme temperatures makes it indispensable in demanding environments such as automotive and oil drilling industries.

Sustainability and Environmental Responsibility

In an era where sustainability is paramount, marbled ebonites stand out as a sustainable alternative to traditional materials. Ebonite is derived from natural rubber, making it biodegradable and eco-friendly. By incorporating marbled ebonites into their products, manufacturers can reduce their environmental footprint and meet the growing demand for sustainable solutions.

Pushing the Boundaries of Innovation

As technology continues to advance, the potential applications of marbled ebonites in the rubber industry are expanding rapidly. From 3D printing to additive manufacturing, innovative techniques are pushing the boundaries of what’s possible with this versatile material. Whether it’s creating intricate prototypes or producing custom designed components, marbled ebonites are poised to play a central role in the future of rubber manufacturing.

Conclusion

In the dynamic landscape of the rubber industry, marbled ebonites represent a harmonious blend of tradition and innovation. With their captivating beauty, functional versatility, and eco-friendly properties, these exquisite materials are reshaping the way we think about rubber manufacturing. As we celebrate their timeless allure and versatility, let us marvel at the endless possibilities they offer for future exploration and discovery.

For More Product Information Visit Us https://kpmrubber.com/ebonites/

About The Author: KPM Team

More posts by KPM Team