Introduction :

Grommets, small ring-like components made of metal, plastic, or rubber, may seem unassuming, but their versatility and practicality have made them indispensable in various industries. These unassuming devices serve essential functions, adding efficiency, safety, and durability to a wide range of applications.

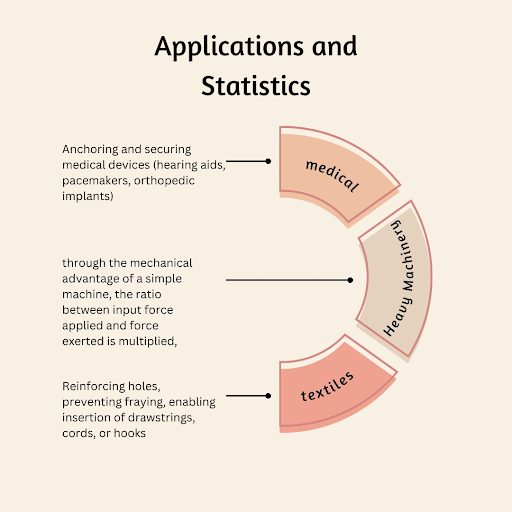

Grommet Applications and Statistics :

Grommets, small ring-like components made of metal, plastic, or rubber, have become indispensable in various industries due to their versatility and practicality. In this article, we explore the diverse applications of grommets and present relevant statistics that highlight their significance in modern manufacturing and design.

Medical Implants and Prosthetic : In the medical field, grommets find application in implants and prosthetics. They are used to anchor and secure various medical devices, such as hearing aids, pacemakers, and orthopedic implants.

Grommet Applications in Manufacturing :

Grommets find extensive use in manufacturing processes to enhance the performance and longevity of products. In textiles, grommets reinforce holes in fabrics, preventing fraying and facilitating the insertion of drawstrings, cords, or hooks. In automotive manufacturing, grommets protect wiring and hoses from abrasion, reducing wear and tear over time.

Cable Management and Electronics :

The cable management industry heavily relies on grommets to organize and protect cables and wires. Grommet-edged cable holes in office furniture and computer desks prevent tangling and promote a neat and clutter-free workspace.

Plumbing and Home Improvement :

Grommets are essential in plumbing applications, ensuring leak-proof seals and preventing pipe chafing. They play a crucial role in faucets, showerheads, and hose attachments, securing hoses and preventing water leaks. In home improvement projects, grommets are employed in curtains, drapes, and blinds to facilitate smooth sliding and reduce fabric wear.

Automotive and Aerospace Industry :

In the automotive and aerospace sectors, grommets contribute to safety and performance. In automobiles, they provide insulation for electrical wiring, ensuring protection against vibrations and mechanical stress.

Grommets in Medical and Healthcare Devices :

The medical and healthcare industries rely on grommets for various applications. In medical equipment, grommets secure tubes and cables, ensuring proper functionality and reducing the risk of dislodgement during critical procedures.

Statistics on Grommet Applications :

According to a report by Grand View Research, the global grommet market is expected to reach USD 18.6 billion by 2028, growing at a CAGR of 5.6%. The rising demand for grommets in automotive, construction, and manufacturing industries is a significant factor driving this growth.

Environmental Benefits of Grommets :

Grommets not only enhance functionality but also contribute to sustainability efforts. By extending the lifespan of products, grommets reduce the frequency of replacements, minimizing waste and resource consumption. Additionally, their role in securing cables and hoses prevents damage and potential leaks, promoting a safer and eco-friendly environment.

Marine and Boating Applications :

In the marine industry, grommets are utilized for securing boat covers, sails, and awnings, offering strong attachment points and weather resistance. They are also essential in the production of inflatable boats and kayaks, ensuring air-tight seals for added buoyancy and durability.

Sporting and Outdoor Equipment :

Grommets are integral components in various sporting and outdoor equipment. In camping gear, they reinforce tent fabric and serve as tie-down points for stakes and guylines. Grommets are also commonly used in backpacks, duffel bags, and other outdoor gear to provide sturdy attachment points for straps and carabiners.

Environmental Compliance :

Certain industries, such as the automotive sector, have strict environmental regulations to adhere to. Grommets play a role in ensuring compliance by preventing fluid leaks and reducing the risk of hazardous materials escaping into the environment. This is crucial in meeting sustainability goals and minimizing the environmental impact of manufacturing processes.

Customization and Personalization :

Grommets offer versatility, allowing for customization and personalization. With the ability to add grommets to specific locations on products, manufacturers can cater to specific customer needs and preferences.

Offshore Oil and Gas Industry :

The offshore oil and gas industry utilizes grommets for cable management and safety. Grommets are employed in underwater cables and pipes, securing them against marine conditions and preventing damage from harsh environments.

Noise and Vibration Reduction :

Grommets also play a role in noise and vibration reduction in various applications. In electronic devices, they dampen vibrations caused by moving components, contributing to quieter operation and improved user experience.

EMI/RFI Shielding :

Electromagnetic Interference (EMI) and Radio-Frequency Interference (RFI) can adversely affect the performance of electronic devices. Grommets with shielding properties are used to protect cables and wiring from such interference, ensuring optimal functionality and signal integrity.

Industrial Applications :

In heavy machinery and industrial equipment, grommets serve as seals and protectors for various components. They prevent dirt, dust, and debris from entering sensitive machinery, maintaining efficiency and prolonging the lifespan of equipment.

Medical Implants and Prosthetic :

In the medical field, grommets find application in implants and prosthetics. They are used to anchor and secure various medical devices, such as hearing aids, pacemakers, and orthopedic implants.

Conclusion :

Grommets, with their diverse applications and impressive statistics, have become essential components in various industries. From manufacturing and electronics to automotive and healthcare, grommets play a vital role in enhancing efficiency and ensuring reliable performance. As industries continue to innovate and evolve, the importance of grommets is expected to grow.

About The Author: KPM Team

More posts by KPM Team