Hard Rubber Rings Key Properties: Uncovering Resilience and Reliability

In the world of sealing solutions, hard rubber rings stand out as versatile and indispensable components. Their unique combination of properties makes them essential across various industries and applications.

In this article, we delve into the key properties of hard rubber rings, exploring their significance and the reasons behind their widespread usage.

Durability and Resilience:

Hard rubber rings, also known as Ebonite rings or Vulcanized rubber rings, are revered for their exceptional durability and resilience.

This quality stems from the vulcanization process, where the rubber material is treated with sulfur and other additives to create strong cross-links between polymer chains.

These cross-links give hard rubber rings their ability to withstand wear, tear, and mechanical stress, ensuring long-lasting performance.

Chemical Resistance:

One of the standout properties of hard rubber rings is their remarkable resistance to a wide range of chemicals, oils, and solvents.

This chemical resistance makes them well-suited for applications in industries such as chemical processing, petrochemicals, and automotive, where exposure to corrosive substances is common.

Hard rubber rings maintain their integrity and sealing effectiveness even in the presence of aggressive chemicals.

Temperature Tolerance:

Hard rubber rings exhibit excellent temperature tolerance, remaining stable and effective across a wide range of temperatures.

This characteristic is crucial in applications that involve extreme temperature fluctuations, such as engine components, industrial machinery, and outdoor equipment.

Their ability to maintain sealing integrity even in challenging thermal conditions makes them reliable choices.

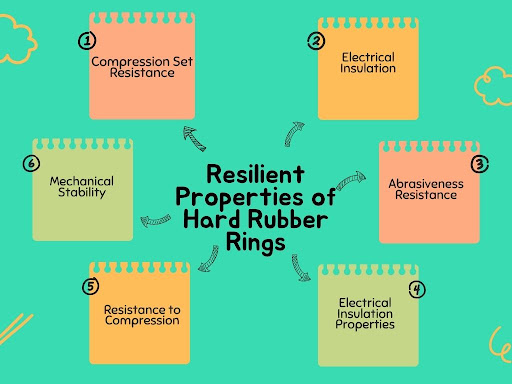

Compression Set Resistance:

Compression set refers to the tendency of rubber materials to lose their original shape after being compressed for a prolonged period.

Hard rubber rings showcase impressive resistance to compression sets, allowing them to bounce back to their original form after being subjected to pressure.

This property ensures consistent sealing performance over time, even in applications where repeated compression and decompression occur.

Electrical Insulation:

Hard rubber rings possess excellent electrical insulation properties their insulating capabilities contribute to the safety and reliability of electrical systems.

This makes them suitable for applications where electrical components need to be protected from environmental factors or where insulation is required to prevent electrical currents from flowing through unintended pathways.

Mechanical Stability:

The vulcanization process imparts a more rigid structure to hard rubber rings, giving them enhanced mechanical stability.

This structural integrity is beneficial in applications where a secure and reliable seal is paramount, such as in pipes, valves, and pumps. Hard rubber rings effectively prevent leaks and maintain the overall functionality of mechanical systems.

Low Water Absorption:

Hard rubber rings exhibits low water absorption, which means they are resistant to swelling or degradation when exposed to water or moisture.

This property is advantageous in applications where maintaining dimensional stability is critical. It also prevents the degradation of sealing properties, ensuring that hard rubber rings remain effective in wet or humid environments.

Abrasiveness Resistance:

The durable nature of hard rubber rings makes them highly resistant to abrasion and wear. This quality is crucial in applications where components experience friction, such as in moving machinery or rotating parts.

Temperature Tolerance in Hard Rubber Rings:

Among the notable properties of hard rubber rings is their exceptional temperature tolerance, enabling them to remain stable and effective across a broad spectrum of temperatures.

This characteristic is particularly vital in applications that encompass significant temperature fluctuations. Whether it’s within engine components, industrial machinery, or outdoor equipment, hard rubber rings stand as reliable choices, maintaining their sealing integrity even amidst challenging thermal conditions.

Resistance to Compression Set:

Compression set is a phenomenon where rubber materials lose their original shape after being compressed over extended periods. Hard rubber rings demonstrate remarkable resistance to compression sets.

showcasing their ability to rebound to their initial form after enduring pressure. This particular trait ensures a consistent sealing performance over time. This is especially valuable in scenarios where repeated compression and decompression cycles occur, safeguarding their effectiveness and longevity.

Electrical Insulation Properties:

Hard rubber rings possess outstanding electrical insulation properties, positioning them as suitable options for applications demanding protection for electrical components against environmental factors.

Moreover, they find significance in situations where insulation is essential to prevent the unintended flow of electrical currents through unintended pathways. These insulating capabilities play a pivotal role in enhancing the safety and dependability of electrical systems.

Enhanced Mechanical Stability:

The vulcanization process lends hard rubber rings a more rigid structure, enhancing their mechanical stability.

This heightened structural integrity proves particularly advantageous in situations where establishing a secure and dependable seal is of paramount importance.

Whether it’s in pipes, valves, or pumps, hard rubber rings effectively thwart leaks, thereby upholding the overall operational effectiveness of mechanical systems.

Limited Water Absorption:

Hard rubber rings display minimal water absorption, rendering them resistant to swelling or deterioration when exposed to moisture or water.

This property holds significance in contexts where maintaining dimensional stability emerges as a critical requirement.

Furthermore, this characteristic prevents any degradation in their sealing capabilities, ensuring that hard rubber rings continue to function optimally even in damp or humid environments.

Resisting Abrasion and Wear:

The innate durability of hard rubber rings equips them with remarkable resistance against abrasion and wear.

This quality assumes vital importance in scenarios where components are subjected to friction, as is the case in moving machinery or rotating parts.

Their capacity to endure abrasive forces significantly contributes to their extended lifespan and heightened reliability, solidifying their place as integral sealing components.

In essence, the temperature tolerance, compression set resistance, electrical insulation properties, mechanical stability, low water absorption, and abrasiveness resistance of hard rubber rings collectively contribute to their indispensable role across various applications.

These properties underscore their capacity to maintain sealing efficacy, endure challenging conditions, and ensure the longevity of systems, thus making them a cornerstone of reliability in the realm of sealing solutions.

Conclusion:

The key properties of hard rubber rings make them versatile and reliable sealing solutions across a wide spectrum of industries.

From chemical resistance to temperature tolerance, these rings exhibit a remarkable blend of qualities that ensure their longevity and effectiveness in diverse applications.

Whether it’s in industrial machinery, automotive components, or critical systems, hard rubber rings continue to play a pivotal role in maintaining efficiency, safety, and functionality.

About The Author: KPM Team

More posts by KPM Team