Nitrile Butadiene Rubber (NBR): Exploring Properties and Characteristics

Nitrile Butadiene Rubber, commonly known as NBR, is a versatile synthetic rubber with a wide range of applications across various industries. Its unique properties and characteristics make it a preferred choice for seals, gaskets,

O-rings, and many other sealing components. In this article, we will delve into the fascinating world of NBR, uncovering its key attributes and how they contribute to its exceptional performance.

Chemical Composition and Structure of NBR:

NBR is a synthetic rubber formed through the polymerization of acrylonitrile and butadiene. The varying ratios of these two monomers during polymerization determine the final properties of NBR.

The presence of acrylonitrile imparts excellent oil and fuel resistance, while butadiene contributes to flexibility and low-temperature performance.

Oil and Chemical Resistance:

One of the standout characteristics of NBR is its remarkable resistance to oils, fuels, and various chemicals.

This property makes NBR ideal for applications in industries where exposure to harsh chemicals is common, such as automotive, petrochemical, and industrial manufacturing. NBR maintains its integrity even when in contact with these substances, preventing degradation and ensuring a reliable seal.

Flexibility and Low-Temperature Performance:

NBR exhibits impressive flexibility over a wide temperature range. It remains pliable even in cold conditions, making it suitable for applications that demand sealing solutions in outdoor or refrigerated environments.

This flexibility ensures that NBR-based seals and gaskets maintain their effectiveness in diverse conditions.

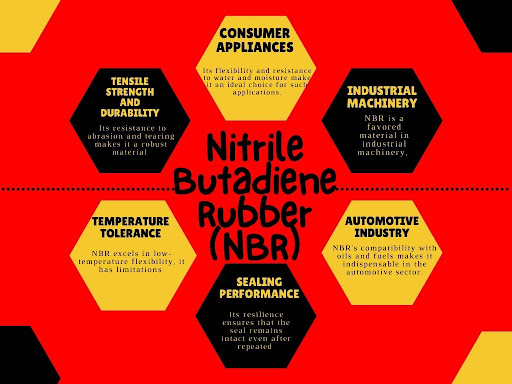

Tensile Strength and Durability:

NBR boasts excellent tensile strength and durability. Its resistance to abrasion and tearing makes it a robust material for applications involving dynamic movements or mechanical stress.

This property is particularly beneficial in industries like automotive and machinery, where components experience constant motion and pressure.

Temperature Tolerance:

While NBR excels in low-temperature flexibility, it has limitations when it comes to high-temperature resistance. Continuous exposure to elevated temperatures can cause NBR to lose its sealing properties and mechanical strength.

NBR-based seals and gaskets are best suited for applications where temperature extremes are not a significant factor.

Sealing Performance:

NBR’s ability to create a reliable seal is a result of its elasticity and compression set resistance. When compressed between two surfaces, NBR forms an effective barrier that prevents leaks and ingress of contaminants.

Automotive Industry:

NBR’s compatibility with oils and fuels makes it indispensable in the automotive sector. It is used for seals and gaskets in engines, transmissions, and fuel systems.

NBR’s ability to withstand exposure to gasoline, diesel, and lubricants ensures the longevity and reliability of automotive components.

Industrial Machinery:

NBR is a favored material in industrial machinery, where it provides sealing solutions for hydraulic and pneumatic systems. Its oil and chemical resistance, coupled with its robustness, make it suitable for various fluid-handling applications.

Oil and Gas Industry:

The oil and gas industry relies on NBR for seals and gaskets in equipment exposed to crude oil, natural gas, and drilling fluids.

NBR’s resistance to hydrocarbons and harsh chemicals is critical for maintaining the safety and integrity of oil and gas operations.

Consumer Appliances:

NBR finds its way into consumer appliances, such as washing machines and refrigerators, where it provides sealing solutions for water and refrigerant systems. Its flexibility and resistance to water and moisture make it an ideal choice for such applications.

Nitrile Butadiene Rubber (NBR) is a synthetic rubber created by polymerizing acrylonitrile and butadiene. The specific ratios of these monomers dictate the ultimate properties of NBR, making it a versatile material with various applications.

Acrylonitrile’s presence imbues NBR with exceptional resistance to oils and fuels, while butadiene contributes to its flexibility and performance at low temperatures.

NBR’s standout quality is its impressive resistance to oils, fuels, and chemicals. This characteristic renders NBR invaluable in industries prone to harsh chemical exposure, such as automotive, petrochemical, and industrial manufacturing.

Its integrity endures even in contact with such substances, ensuring reliable seals without degradation.

NBR showcases remarkable flexibility across a broad temperature spectrum. Its pliability in cold conditions suits applications necessitating sealing solutions outdoors or within refrigerated environments.

This adaptability guarantees the sustained efficacy of NBR-based seals and gaskets in various surroundings.

The rubber exhibits excellent tensile strength and durability. Its resistance to abrasion and tearing endows it with robustness, particularly valuable in sectors like automotive and machinery, where components endure constant motion and mechanical stress.

Though NBR excels in low-temperature flexibility, it does have limitations in terms of high-temperature resistance. Prolonged exposure to elevated temperatures can lead to the compromise of NBR’s sealing capabilities and mechanical strength.

Conclusion:

Nitrile Butadiene Rubber (NBR) is a versatile and valuable material known for its exceptional oil resistance, flexibility, durability, and sealing performance.

Its diverse applications across industries underscore its significance in maintaining the integrity and reliability of various components and systems. Whether in the automotive, industrial, or consumer sectors, NBR continues to play a crucial role in ensuring effective seals and gaskets that withstand the challenges of modern engineering.

About The Author: Seoteam

More posts by seoteam