O-rings are the unsung heroes of countless industrial applications, sealing connections and ensuring the smooth operation of machinery and systems.

Among the array of O-ring materials available, polyurethane (PU) has emerged as a versatile and dependable choice.

Renowned for its durability, resilience, and adaptability, polyurethane O-rings have found their place in diverse industries, ranging from manufacturing and automotive to aerospace and beyond.

In this article, we delve into the world of polyurethane O-rings, exploring their characteristics, advantages, and applications that make them indispensable.

Understanding Polyurethane: A Remarkable Polymer:

Polyurethane is a synthetic polymer that exhibits a unique blend of qualities, making it an excellent candidate for O-ring applications.

Its molecular structure provides remarkable elasticity, chemical resistance, and resistance to wear and tear. This combination of attributes grants polyurethane the ability to excel in demanding environments and challenging conditions.

Advantages of Polyurethane O-Rings:

Polyurethane O-rings offer unparalleled resilience, allowing them to withstand pressure changes, mechanical stress, and temperature fluctuations. This characteristic is crucial in environments where reliability is paramount.

Wear and Abrasion Resistance:

PU O-rings exhibit exceptional wear and abrasion resistance, making them suitable for applications involving sliding or rubbing surfaces. This property extends its lifespan, reducing maintenance needs.

Sealing Performance:

The elasticity of polyurethane ensures effective sealing, preventing leaks and maintaining the integrity of the systems they are employed in. Their ability to create a secure and reliable seal is vital for a range of industries.

Chemical Resistance:

Polyurethane is known for its resistance to many chemicals, oils, and solvents, making PU O-rings suitable for applications where exposure to corrosive substances is likely.

Tear Strength:

PU O-rings boast high tear strength, enabling them to resist damage from sharp edges or high-pressure situations. This property is essential for maintaining consistent sealing performance.

Low Compression Set:

Polyurethane’s low compression set ensures that the O-rings retain their original shape after compression, enabling them to maintain their sealing effectiveness over time.

Wide Temperature Range:

PU O-rings exhibit stability across a wide range, ensuring they perform reliably even in extreme conditions.

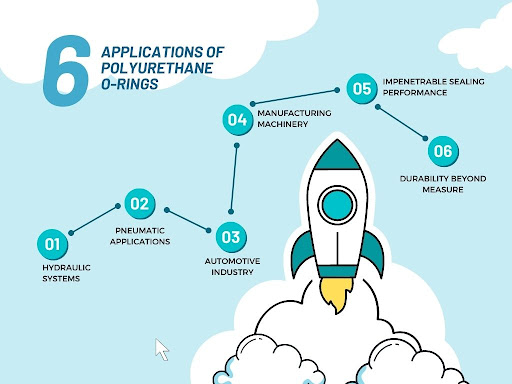

Applications of Polyurethane O-Rings:

Hydraulic Systems:

In hydraulic systems, where pressure and movement are constant, polyurethane O-rings provide effective sealing and contribute to the overall efficiency of the system.

Pneumatic Applications:

Polyurethane’s resilience makes it suitable for pneumatic applications, where O-rings must endure repeated cycles of compression and decompression.

Automotive Industry:

Polyurethane O-rings find applications in various automotive components, including fuel systems, braking systems, and suspension systems, due to their durability and chemical resistance.

Manufacturing Machinery:

In manufacturing, where machinery operates continuously, polyurethane O-rings ensure that the machinery functions smoothly and efficiently, reducing downtime.

Oil and Gas:

Polyurethane’s resistance to chemicals and wear makes it a valuable choice in the oil and gas industry for sealing applications in harsh environments.

Durability Beyond Measure:

Endurance against wear and tear is a hallmark of polyurethane O-rings. These components maintain their integrity and functionality even in scenarios where friction and abrasion are incessant, contributing to prolonged service life.

Impenetrable Sealing Performance:

The elasticity inherent to polyurethane empowers O-rings to create airtight seals that staunchly guard against leaks and preserve the integrity of systems. This quality is particularly indispensable in environments where fluid containment is of paramount importance.

Dynamic Temperature Tolerance:

Polyurethane O-rings exhibit a remarkable ability to retain their performance across a wide spectrum of temperatures. This adaptability ensures that these components remain effective and reliable in fluctuating thermal conditions.

Mechanical Versatility:

These O-rings possess the fortitude to withstand mechanical stress and pressure changes, making them an ideal choice for applications where machinery undergoes frequent movement, compression, and decompression.

Low Compression Set:

The capacity to rebound to their original shape post-compression, also known as low compression set, distinguishes polyurethane O-rings. This unique trait ensures consistent sealing performance even after enduring prolonged periods of pressure.

A Force to Reckon With: Polyurethane’s Impact:

The exceptional attributes of polyurethane redefine the standards of O-ring performance. Its dynamic composition, marked by elasticity, resistance, and durability, empowers these components to thrive under demanding circumstances.

Whether in industrial machinery, automotive systems, or complex aerospace applications, polyurethane O-rings stand as a testament to human ingenuity and their ability to adapt to the intricacies of modern engineering.

In a world where reliability is non-negotiable, polyurethane O-rings emerge as a force to reckon with, revolutionizing the landscape of sealing technology and fortifying critical systems across industries.

Conclusion:

Polyurethane O-rings the unseen guardians of efficiency stand as a testament to human innovation in material science. Their remarkable combination of resilience, wear resistance, sealing performance, and chemical stability make them a formidable choice for a wide range of applications.

In industries where efficiency, reliability, and longevity are paramount, these unassuming components play a pivotal role. As technology advances and industries continue to evolve, the versatility and performance of polyurethane

O-rings ensure that they will remain a staple in the engineering world, silently upholding the efficiency and functionality of critical systems.

About The Author: Seoteam

More posts by seoteam