Rubber is a versatile material with widespread applications across industries, known for its elasticity, durability, and resilience. Two common types of rubber used in various applications are Natural Rubber (NR) and Ethylene Propylene Diene Monomer (EPDM). While they may appear similar at first glance, they possess distinct properties that make them suitable for specific purposes. Understanding these differences is crucial for selecting the right material for a particular application.

What is Natural Rubber (NR)?

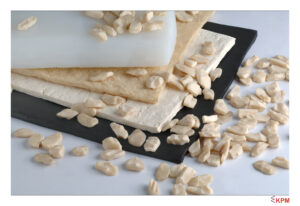

Natural Rubber originates from the latex sap of the Hevea brasiliensis tree. Its molecular structure primarily consists of cis-1,4-polyisoprene units, imparting high tensile strength and tear resistance. NR is known for its exceptional elasticity and resilience, making it ideal for applications requiring flexibility and abrasion resistance.

What is EPDM?

EPDM is a synthetic rubber composed of ethylene, propylene, and a small amount of diene monomer. This composition grants EPDM excellent weather resistance, ozone resistance, and thermal stability. EPDM is commonly used in outdoor applications such as roofing membranes, seals, and gaskets due to its ability to withstand exposure to harsh environmental elements.

How do their Chemical Compositions Differ?

NR is obtained from a renewable natural source, making it biodegradable and environmentally friendly. In contrast, EPDM is produced through a polymerization process using petroleum derived materials, making it less sustainable but highly durable.

What are their Key Physical Properties?

NR typically exhibits higher tensile strength and tear resistance compared to EPDM. However, EPDM showcases superior resistance to heat, UV radiation, and chemicals, making it suitable for applications subjected to extreme conditions.

What about Cost and Availability?

Natural Rubber tends to be more expensive due to its extraction process and limited geographical availability. EPDM, being a synthetic rubber, is more cost-effective and readily available in various formulations to meet specific application requirements.

In conclusion, while both NR and EPDM offer unique advantages, understanding their differences is essential for selecting the most appropriate material for a given application. Factors such as environmental conditions, performance requirements, cost, and sustainability goals should be carefully considered to make informed decisions and optimize outcomes in industrial projects.

Get a quote for NR and EPDM products: https://kpmrubber.com/contact-us/

About The Author: KPM Team

More posts by KPM Team