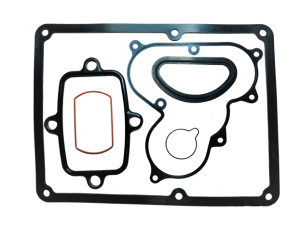

A polymer-based ring with custom cross-sections to solve the specific sealing requirements. KPM has the facility to produce the thinnest from 0.65mm to 850mm size profile rings.

The material selection and the property selection can be against the custom requirement. Although the geometric configuration of the seal is critical, it is also very important to select the most appropriate compound for the specific application.

Having a team of experts with decades of experience, KPM can accurately mold the profile rings as per the criticality in every section. Profile ring is a polymer-based ring with custom cross-sections to solve the specific sealing requirements. KPM has the facility to produce the thinnest from 0.65mm to 850mm size profile rings with strict adherence to the close tolerance as per prints

KPM has the tear trim technology providing minimal flash parts and flash free parts reducing the scrap rate. The molding processes in KPM molding shop includes

Compression molding

Vacuum compression molding

Transfer molding

Vacuum transfer molding

Injection molding.

In addition to delivering parts on time, we provide the parts with 100% inspection and zero PPM. Our in-house testing has the facility to perform a non-contact measuring system to ensure you of the dimensional stability. Our laboratory is equipped with industry-leading technology to reassure you of the quality and performance of our parts.

Although the geometric configuration of the seal is critical, it is also very important to select the most appropriate compound for the specific application. The material selection and the property selection can be against the custom requirement.

Our technical team can collaborate with the customer to provide solutions on the selection of material and to achieve the application-specific property. Contact us to get the competitive cost for your enquiry !